Physical and chemical treatment equipment

1.Mixer

Mixers are applied in chemicals addition, flocculation, coagulant and chemical dissolution, etc.

Features

- Customized design.

- Impeller and shaft are made of stainless steel(SUS304).

- SEW gear reducer.

2.Dissolved air floatation equipment

Dissolved air flotation (DAF) is a wastewater treatment process that removes suspended matters such as oil or solids. The removal is achieved by fine air bubbles floatation due to the depressure process of pressurized air-water solution. The the floated suspended matters are removed by skimmer.

3.Fered-Fenton equipment

4.Fluidized bed Fenton (FBR-Fenton) reactor

5.Fluidized bed Crystalization (FBC) reactor

6.Fluidized bed reactor for Fe/Mn removal

7.Pressurized sand filter

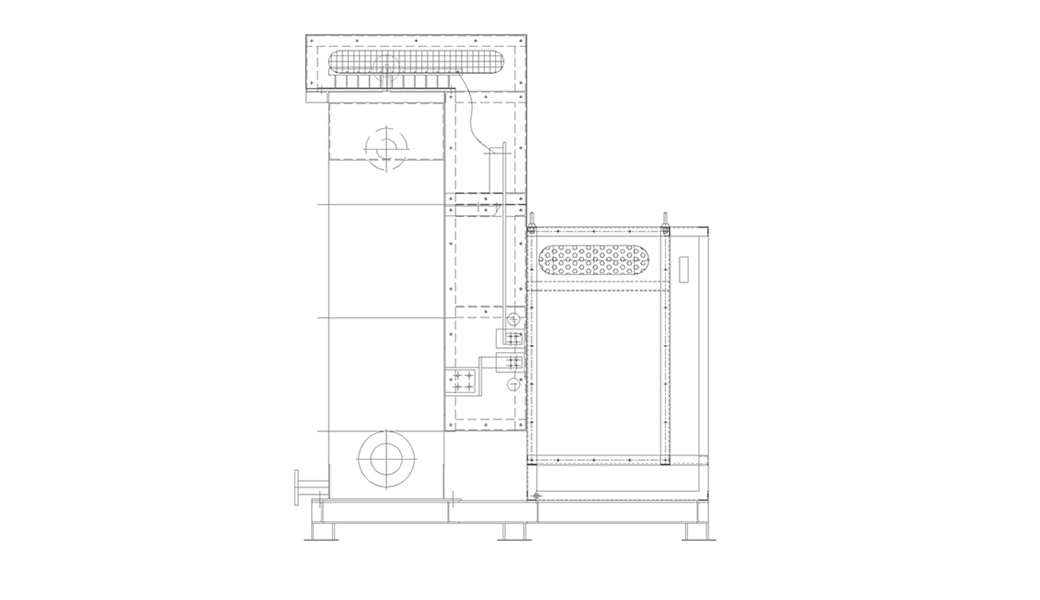

8.Continuous sand filter

The principle of continuous sand filter is that raw water enters the bottom of the tank and flows up through the media (sand) for suspended solids filtration. An air lift pump is applied in continuous sand filter to draw the media from the bottom of the tank up into the wash chamber. As the media is released, the filtered solids are separated from the media. Then the filtrate carries out the filtered solids out of the tank and the washed media falls down to the media bed for continued use.

Application

- Drinking water treatment

- Process water treatment

- Process water recovery

- Industrial wastewater treatment

- Sewage treatment

- Paper mill plant

- Pharmaceutical plant

- Mining industry

- Copper smelting plant

- Metal processing industry

- Municipal and wastewater treatment plant

Features

- High and stable filtration effiency.

- Easy to operate.

- Continuous water production and no backwash equipments such as backwash tank, pump and control system required.

- Applicable in high SS wastewater.

- Low footprint compared to conventional sand filter.

9.Activated carbon adsorption equipment

10.Ion exchange resin equipment