Floating decanter system of Sequential Batch Reactor

Floating decanter system of Sequential Batch Reactor

Sequential Batch Reactors(SBR) is an advanced type of activated sludge process. The principle is that aerobic microorganisms decompose soluble organic containment as substrate and produce biomass during metabolism.

SBR reactor treats wastewater in batches, and the treatment process usually contains five stages: Fill, React, Settle, Decant and Idle. The period of each stage can be adjust based on water quality change.

Floating decanter system is the key part equipment applied in SBR reactor which can reduce the SS in effluent in decant stage.

Features

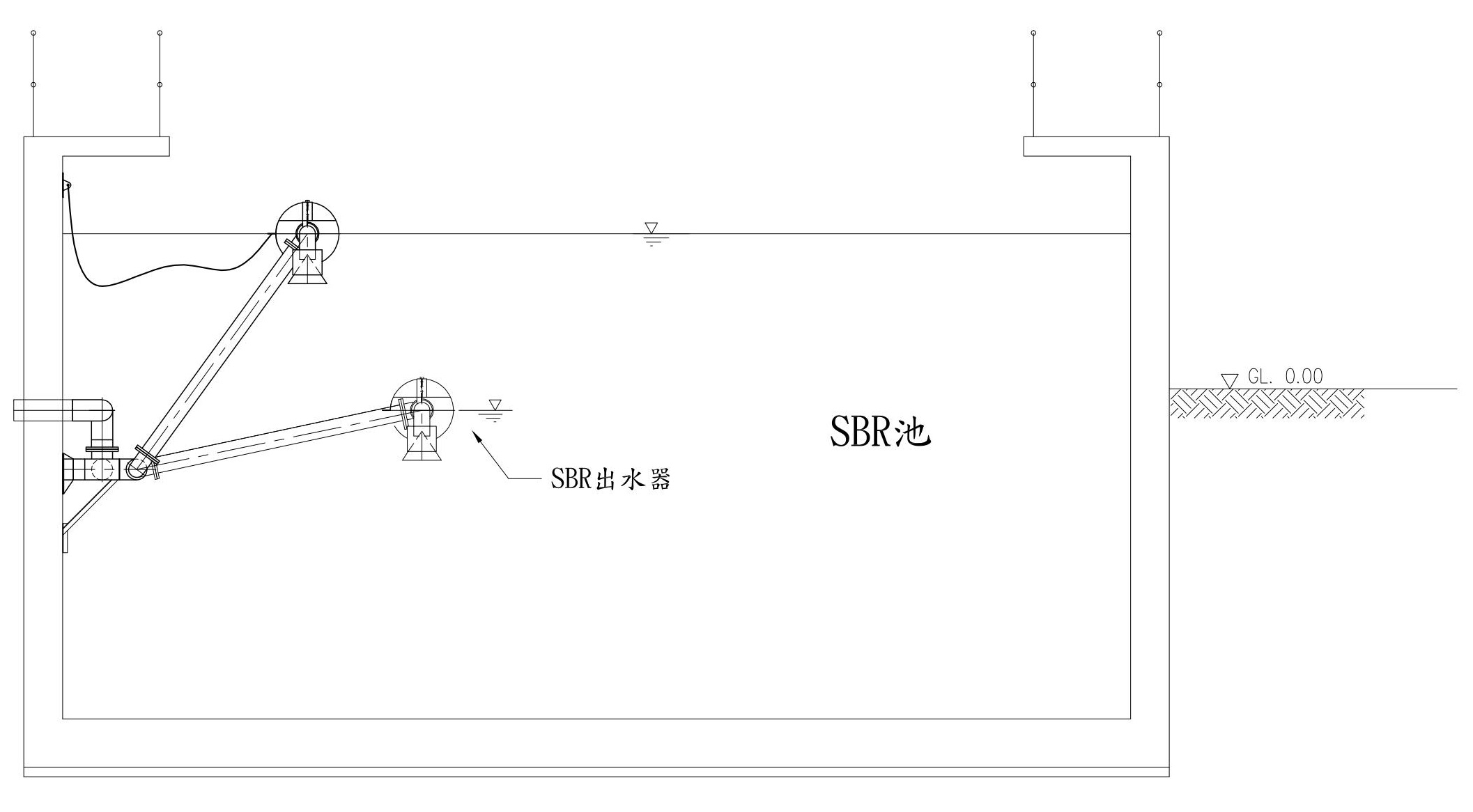

- Decant of SBR is by floating decanter system, which is composed of floating decanter, drainage pipe, screen and support.

- The functions of floating decanter are increasing the buoyancy of the system and stopping the scum flowing out with the effluent. In Fill, React and Settle stages, the floating decanter is filled with air and on the high water level of reactor. When the stage of Decant starts, the upper treated water flows through the drainage pipe and stops until the water level at low.

- Material of stainless steel (SUS304).

- There's no powre required, vibration and noise.